At a chemical plant in North England, a new production line was installed. This meant excess steam from reactor cooling was available.

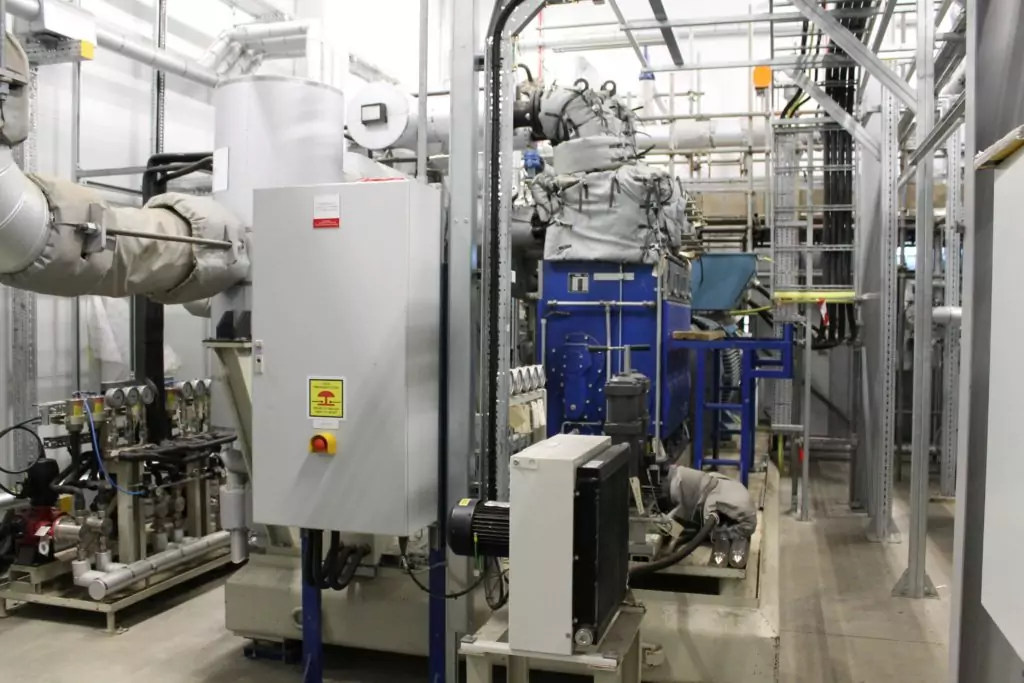

The decision was taken to recycle the complete heat content in the steam by compressing it so it could be used again as process steam for other applications. For this purpose Spilling piston steam compressors were chosen.

The installation of the new production line in the chemical plant took longer than originally planned. Therefore, the final commissioning of the steam compressors did not take place until summer 2021.

During commissioning it was shown that the steam compressors have a better delivery rate than expected, and use about 10% less electricity than predicted.

By recycling the excess steam rather than producing it with a gas fired boiler, the plant saved around 14,000 tonnes of CO2 per year.